PIGMENTS

Pearlescent

The main property of pearlescent pigments is to mimic the inherent gleam and luster of natural pearls. Pearlescent pigments provide iridescent effect which allow color stylings for different viewing angles.

Pearlescent pigments are usually micas, synthetic or natural that have been coated with titanium dioxide, iron oxide or another metal oxide. Platelets of coated mica can vary in size, shape and thickness, which will determine the sparkle.

With its outstanding visual and technical properties, pearlescent pigments are widely used in a variety of applications, such as:

- Decorative coatings

- Pprinting inks

- Plastics

- Cosmetics

PIGMENTS

Aluminum Paste

Aluminum paste are used in applications ranging from coatings, plastics and printing inks. Pigments are produced from atomized aluminum powder and almost exclusively manufactured through a wet-milling process and available in both leafing and non-leafing grades.

PIGMENTS

Organic Pigment

Our organic pigments range is consist on:

- Azo pigments

- Phthalocyanine pigments

- Carbazole pigments

They have bright color, high color strength, and are available in red, yellow, blue, green, and violet.

Our inorganic pigments are used in numerous application in various industries:

- Offset inks

- Water-based inks

- Solvent-based inks

- Coatings

- Plastics

- Textile printing

PIGMENTS

Iron Oxide

Our iron oxides are available in red, yellow, green, brown, and black. They are available both in regular powder and micronized powder forms.

All products are recognized for their outstanding color stability, excellent light fastness, weather stability, and chemical resistance.

Iron oxides are used in numerous application in various industries:

- Architectural paint

- Corrsion protective coating

- Powder coating

- Colored concrete

- Colored asphalt

- Flooring

- Plastic

PIGMENTS

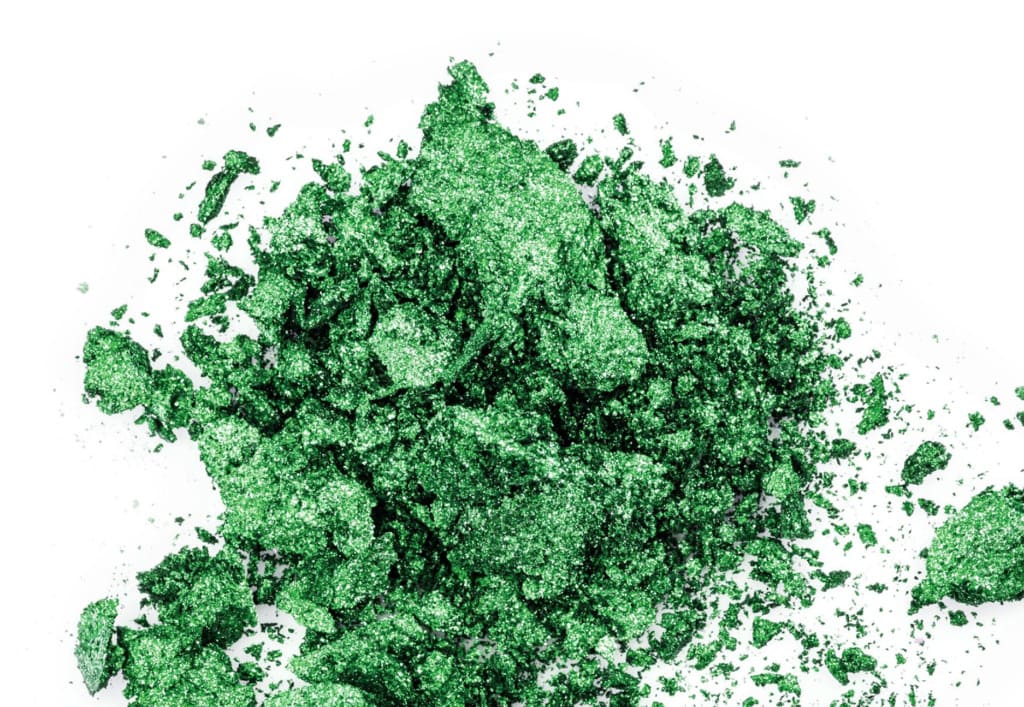

Glitter

Glitter is an assortment of small, reflective particles that come in a variety of shapes, sizes, and colors. Glitter particles reflect light at different angles, causing the surface to sparkle or shimmer. Glitter is similar to confetti, sparkles and sequins, but somewhat smaller

PIGMENTS

Phosporescent

Photoluminescent pigments or phosphorescent pigments are commonly referred to as glow-in-the-dark pigments.

They have the ability to absorb energy and store it. Once the light source is removed, they begin to give up that stored energy in the form of light. The most common glow is the yellow-green or blue-green shade.

Our photoluminescent pigment is non-toxic, harmless, non-radioactive, and has higher luminosity and longer afterglow time compared to traditional photoluminescent pigments.

PIGMENTS

Transparent Oxide

Transparent iron oxides are multi-functional nontoxic pigments that combine a range of color shades with excellent UV absorption, transparency and weathering stability. It is possible by the blending of transparent iron oxide pigments with other pigments to achieve a range of standard wood shades.

When pigments particle size is less than half-wavelength and fully dispersed in mediators, it will come to light’s diffraction with transparent effects, transparent iron oxide pigments with nanometer size are the special material that formed on basis of this principle. Transparent iron retain chemical compositions and crystals of gen iron oxides, so they own excellent chemical stability, resistant to acids, alkali, solvents, water and oil. Transparent iron oxide red can be heat resistant for more than 300 degree Celsius. It’s well known that general grade iron oxides own excellent light fastness, while transparent iron oxides with nanometer size have more strong ultraviolet absorption. So, transparent iron oxides are not only excellent light fastness, but also enhanced anti-aging due to ultraviolet absorption nanometer size transparent iron oxides own high saturation and tinting strength, because they change general grade iron oxides absorbtion and scattering of visible light.

To meet different requirements, we offered transparent iron oxide pigment powders and transparent iron oxide pigment dispersions. They are widely used in wood coatings, automobile coatings, plastic coatings, metal coatings, architectural coatings, artist colors, high temperature glass ink etc.

PIGMENTS

Solvent Dyes

Natural or synthetic substance used to add a color or to change the color of something. Dyes are the coloring material that color commodities of our day to day use. Dyes are applied everywhere, from Plastic toys for children to that fabrics you wear, from food to wood; hardly there is any industry where dyes are not used commercially. A dye is a colored substance that has an affinity to the substrate to which it is being applied. It is an ionising and aromatic organic compounds. The dye is generally applied in an aqueous solution, and may require a mordant to improve the fastness of the dye on the fiber.

PIGMENTS

Carbon Black

Carbon black is composed of fine particles consisting mainly of carbon. It gets manufactured in highly controlled processes and contains more than 95% pure carbon. The carbon black particles are fused into chain-like aggregates, which define the structure of individual carbon black grades. Depending on the production process, carbon black types differ in particle size, surface area, porosity and many other characteristics. In most coatings applications, the primary function of the carbon black is as a pigment. Carbon black is excellent coloring agent as black pigment, and therefore is widely used for printing inks, resin coloring, paints, and coatings. Higher color carbon blacks generally have higher surface area. This surface area leads to higher required dispersant loading, dispersion energy, and other processing requirements. A carbon black that is well dispersed will provide deeper color than the same material when poorly dispersed.

Like particle size, the size of the structure also affects the blackness and dispersibility of carbon black. Generally, the increase of structure size improves dispersibility but lowers blackness. Carbon black with a larger structure in particular shows an excellent conductive property. Some applications of carbon black are shown below.

Coloring Agent for Inks and Paints: Carbon black is widely used for printing inks, paints and toners. Carbon black has higher tinting strength compared to iron oxide black or organic pigments.

- Coloring Agents for Plastics: Carbon black is suitable for coloring plastic resins and films because it has high tinting strength and is thermally stable. Carbon black is also excellent for absorbing ultraviolet light, providing better outdoor resistance. Resins with carbon black, such as automobile bumpers, wire coverings and pipe linings will get improved weather resistance and durability.

- Electric Conductive Agent: Carbon black is also used as an excellent antistatic agent. Its particles have the graphite-type crystalline structure, which serve as conductive filler in plastics, elastomer, paints, adhesives, films, and pastes.

PIGMENTS

Fluorescent

We offer high quality daylight fluorescent pigments for a

wide range of applications.

Paints & Coatings

- Water & solvent based paints

- Paper coatings / clay coatings / fabric coatings

- Aerosols

- Poster & artist colors / hobby paints

- Powder Coatings

Printing Inks

- Screen inks / flexographic inks / gravure inks

- Highlighter inks

Plastics

- Injection / extrusion / blowing molded polyolefins

- Masterbatches

- Vinyl plastisols / Calendering

- EVA / TPE / Rubber

Textile Printing & Dyeing

Miscellaneous

- Crayons / candles / chalks / clays / playdough

- Nondestructive detection